How to choose the right product depends on your application. We always suggest you contact us to discuss your needs

Product

Kaneka PVC plastic additive is suitable for various applications, including extruded pipe, extruded profile, calendered sheet, salivated sheet, injection molded parts, foamed products, blown film and so on

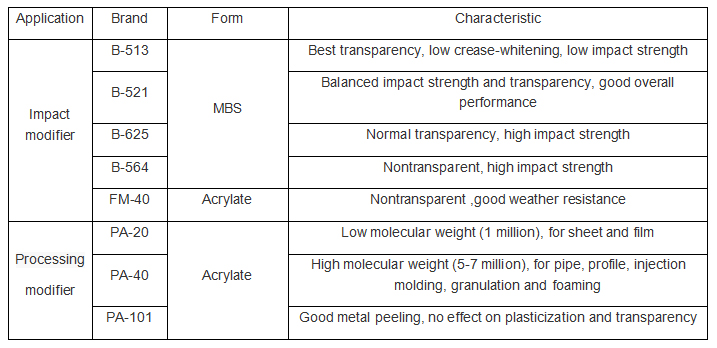

Kaneka® PA Processing modifer–Acrylate polymer(ACR) can provide PVC with efficient, smooth surface, rapid fusion and highly homogeneous melt, and improve processing performance and product surface effect. Used in PVC foaming process to stabilize melt strength and produce lower density, higher foaming rate and very fine cell structure.

Kaneka ® B Impact modifier – The ternary copolymer MBS of methyl methacrylate (M), butadiene (B) and styrene (S) has a typical core-shell structure, which improves the impact resistance of PVC materials. The excellent balance between transparency and impact resistance is especially suitable for transparent PVC products

.Kaneka ® FM Impact modifier – Acrylate polymer(ACM), a weather resistant impact modifier, is particularly suitable for outdoor PVC products